What is Double-Sided PET Tape ?used for?

Double Sided PET tape is made of PET film as the base material and coated with special acrylic pressure-sensitive adhesive on both sides. It has excellent adhesion, good Initial Tack and stickiness, good high humidity resistance, excellent aging resistance, excellent high and low temperature shear resistance, strong Tensile Strength and other characteristics.

Composition and Structure

The Double-Sided PET Tape is composed of a PET film as the base material, coated with a special acrylic pressure-sensitive adhesive. This unique structure enables it to be adhered on both sides, providing superior bonding performance compared to traditional double-sided tapes. The high tensile strength of the PET film ensures its durability and reliability in various applications.

Features of PET Substrate

PET, short for Polyethylene Terephthalate, is the most common type of thermoplastic polyester. Its chemical formula is (C10H8O4)n, with a molar mass of 192g/mol for the repeating unit. PET material possesses characteristics such as high crystallinity, high density, low water absorption, high mechanical strength, excellent dimensional stability, low friction coefficient, excellent electrical properties, and good chemical resistance. These properties enable double-sided PET tape to exhibit outstanding performance in bonding and fixation applications.

Advantages

1.High adhesion: Double-Sided PET Tape has strong bonding strength, capable of securely adhering various materials including plastic, rubber, metal, glass, etc.

2.Excellent temperature resistance: PET double-sided adhesive tape can be used at high temperatures, with long-term temperature resistance up to 150°C and even short-term temperature resistance exceeding 200°C, providing reliable performance in high-temperature environments.

3.Strong anti-aging property: Double-Sided PET Tape exhibits good resistance to aging, maintaining its adhesive properties for an extended period without easy detachment.

4.Environmentally friendly and non-toxic: Double-Sided PET Tape is primarily made of eco-friendly materials and does not contain harmful substances, ensuring its safety for both the environment and human health.

5.Wide range of applications: Double-Sided PET Tape is widely used in electronics, automotive, construction, medical, packaging, and other fields, meeting various adhesive requirements.

6.Compliance with ROHS environmental standards: It meets the requirements of ROHS standards, reflecting the environmental safety of the tape material.

7.Waterproof and moisture-proof: Double-Sided PET Tape remains stable even under high humidity conditions. Its UV resistance and anti-aging characteristics ensure long-term effectiveness in outdoor or high-temperature environments.

Application

Automotive industry: Used for decorative strips, sealing strips, car air conditioning, nameplates, speakers, etc.

Construction industry: Used for fixing stainless steel plates in elevators, adhering building decorations.

Electronics industry: Used for nameplates of home appliances, fixing electronic components, membrane switches, etc.

Daily necessities: Used for soundproofing, insulation, sticking daily life products, adhering mobile phone die-cutting accessories, etc.

1.Bonding and fixation of protective films for modules.

2.Bonding and fixation of nameplates and membrane switches in the home appliance industry.

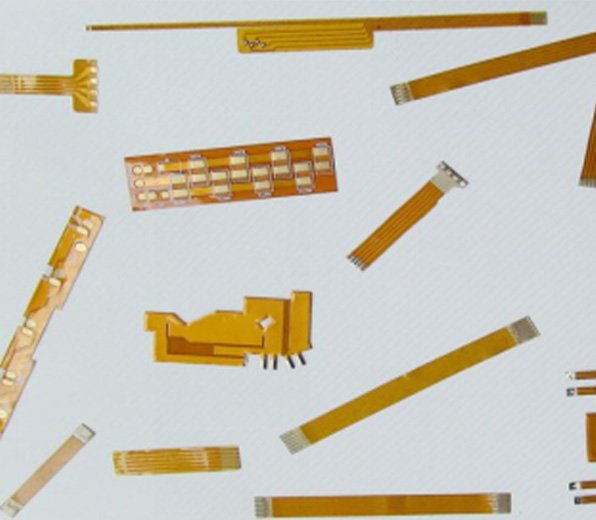

3.Bonding and fixation of FPC (Flexible Printed Circuit) boards.

4.Bonding and fixation of OLED (Organic Light-Emitting Diode) internal structures.

5.Bonding and fixation of protective films for modules.

6.Temporary fixation and adhesion of mobile phone components.

7.Bonding of internal graphite sheets in mobile phones.

8.Fixation and adhesion of rubber foot pads.

9.Bonding of microwave oven door mesh spray plates.

1 0.Used for the bonding and fixation of backlight modules, electronic components, dust nets, LED reflector modules, etc.

|

|

| Bonding of backlight modules | Bonding and fixation of FPC (Flexible Printed Circuit) |

|

|

| Fixation of LED reflector modules | Adhesion of electronic components |

|

|

| Adhesion of OLED internal structures | Adhesion of graphite sheets in mobile phone internals |

The Technical Data Sheet of You-San Double-Sided PET Tape

Product Code Color Total Thickness [um] Backing [mm] Adhesive Initial Tack

[mm]180°Peel Strength

[N/inch]Retentivity

[hour]Long-Term Temperature Resistance [℃] Short-Term Temperature Resistance [℃] P3205A Transparent 50 0.012 Acrylic ≥100 ≥11 ≥24 80 120 P3210A Transparent 100 0.012 Acrylic ≥100 ≥20 ≥24 80 120 P3215A Transparent 150 0.012 Acrylic ≥100 ≥20 ≥24 80 120 P3217A Transparent 170 0.012 Acrylic ≥50 ≥20 ≥24 80 120 P3203G/B Transparent/Black 30 0.012 Acrylic ≤150 ≥7 ≥24 80 120 P3205G/B Transparent/Black 50 0.012 Acrylic ≤150 ≥8 ≥24 80 120 P3208G/B Transparent/Black 80 0.012 Acrylic ≤120 ≥10 ≥24 80 120 P3210G/B Transparent/Black 100 0.025 Acrylic ≤100 ≥12 ≥24 80 120 P3213G/B Transparent/Black 125 0.025 Acrylic ≤100 ≥14 ≥24 80 120 P3216G/B Transparent/Black 160 0.025 Acrylic ≤100 ≥15 ≥24 80 120 P3220G/B Transparent/Black 205 0.025 Acrylic ≤100 ≥17 ≥24 80 120 P3208M Transparent 80 0.012 Acrylic ≤120 ≥10 ≥24 80 120 P3210M Transparent 100 0.012 Acrylic ≤100 ≥12 ≥24 80 120 P3216M Transparent 160 0.012 Acrylic ≤100 ≥15 ≥24 80 120 P3220M Transparent 205 0.012 Acrylic ≤100 ≥17 ≥24 80 120 P3220LM Transparent 205 0.012 Acrylic ≤100 ≥18 ≥24 40 60 P3200 Transparent 80-150 0.025 Acrylic+

silicone≤100 ≥8-15 ≥3 30 40 P3205AB Transparent/Black 50 0.012 Acrylic+

silicone≤100 A≥8

B≥7≥24 80 120 P3208AB Transparent/Black 80 0.025 Acrylic+

silicone≤100 A≥10

B≥8≥24 80 120 P3210AB Transparent 100 0.025 Acrylic+

silicone≤100 A≥16

B≥12≥24 80 120 P3213AB Transparent 125 0.025 Acrylic+

silicone≤100 A≥14

B≥12≥24 80 120 P3214AB Transparent 140 0.025 Acrylic+

silicone≤100 A≥18

B≥14≥24 80 120