PE protective film uses PE film as carrier and coated with high performance acrylic pressure sensitive adhesive. It has good flexibility, good fit, good adhesion and is environmentally friendly and non-toxic.

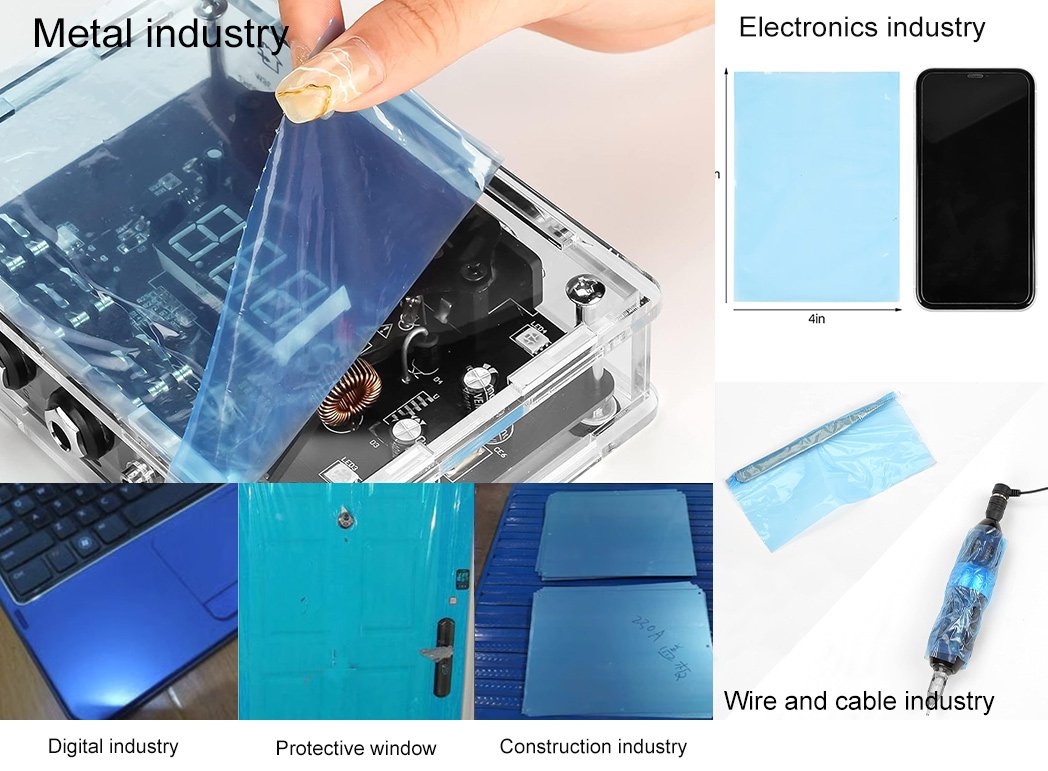

1. Hardware industry: computer cases, galvanized sheet stamping, aluminium plates, stainless steel plates, titanium plates, plastic steel plates, glass plates, solar panels.

2. Optoelectronic industry: LCD liquid crystal display, backlight board, cold light sheet, membrane switch, mobile phone screen, etc.

3. Plastic industry: ABS, PP injection molding products, PVC plates, acrylic plates, meters, plastic lenses, spray paint parts surface protection, etc.

4. Printing industry: PVC, PC board, aluminum plate, film and other printed nameplate surface protection, etc.

5. Wire and cable industry: the protection of shaft-mounted copper wire, semi-finished products, finished products, rolled products, can effectively prevent dust pollution, anti-oxidation, anti-fouling effect.

6. Electronics industry: in the production of time, generally need to be used to protect the finished products and semi-finished products made up, in the assembly line is not easy to appear scratch and touch bad!

7. Mobile phone digital industry: mobile phone screen protection film, is available to install the table mobile phone body, screen a protection.

| Property | ||||||||||

| Product Code Technical Parameters |

P4103 | P4104 | P4105 | P4106 | P4107 | P4108 | P4110 | P4112 | P4115 | P4105E |

| Color/Apperance | Transparent/White/Blue(Plain,Grid) | |||||||||

| Total Thickness[mm] | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.1 | 0.12 | 0.15 | 0.05 |

| Backing | PE | PE | PE | PE | PE | PE | PE | PE | PE | PE |

| Adhesive | Acrylic | |||||||||

| 180°Peel Strength[g/inch] | 1~1200 | |||||||||

| Elongation At Break[%] | ≥200 | |||||||||

| Long-Term Temperature Resistance[℃] | 60 | |||||||||

| Short-Term Temperature Resistance[℃] | 100 | |||||||||

PE Protective Film, polyethylene protective film, is a film made of polyethylene material. It has excellent mechanical properties, chemical stability and processing performance, and is widely used in many fields to provide effective protection for items.

Application scenarios

1.Hardware Industry: In the manufacturing and transportation of computer cases, galvanized sheet stamping, aluminum plates, stainless steel plates, titanium plates, plastic steel plates, glass plates, solar panels, etc., PE protective film effectively prevents scratches, fingerprints, and contamination, ensuring that the product surfaces remain clean and intact for final assembly and installation.

2.Optoelectronic Industry: During the production and assembly of LCD liquid crystal displays, backlight boards, cold light sheets, membrane switches, mobile phone screens, etc., PE protective film provides the necessary protection to avoid scratches and contamination during manufacturing and assembly, ensuring the display effect and quality of the products.

3.Plastic Industry: For ABS, PP injection molding products, PVC plates, acrylic plates, meters, plastic lenses, and surface protection of spray-painted parts, PE protective film not only safeguards the surfaces from dust and scratches but also provides an additional layer of abrasion and scratch resistance, ensuring products remain in optimal condition during storage and transportation.

4.Printing Industry: For surface protection of PVC, PC boards, aluminum plates, films, and other printed nameplates, PE protective film prevents ink contamination and scratches, ensuring that printed products remain clear and aesthetically pleasing during storage and display.

5.Wire and Cable Industry: PE protective film is used in the wire and cable industry to protect shaft-mounted copper wire, semi-finished products, finished products, and rolled products. It effectively prevents dust pollution, provides anti-oxidation properties, and offers anti-fouling effects, ensuring the quality and performance of wire and cable products.

6.Electronics Industry: In electronics production, PE protective film is commonly used to protect finished and semi-finished products. This protective film prevents scratches, contamination, and reduces the likelihood of damage during assembly line processes, ensuring the reliability and durability of electronic products.

7.Mobile Phone and Digital Industry: PE protective film for mobile phone screens is a popular choice. It can be easily installed on mobile phone bodies and screens, providing a sturdy and transparent protective layer that prevents scratches, fingerprints, and contamination while maintaining screen clarity and touch sensitivity.

size and color

The size and color of PE Protective Film can be customized according to different application requirements.

Size: Common sizes include standard widths such as 1 meter, 1.2 meters, 1.5 meters, etc. The length can be customized according to actual needs. In addition, we can also customize special shapes of protective films as needed, such as round, oval, etc.

Color: PE protective film is generally transparent, allowing you to observe the status of the protected items. At the same time, in order to meet certain special needs, such as marking, distinguishing, etc., protective films of different colors such as blue, green, and yellow can also be produced.

Specification data