Filament tape is made from transparent PET/PP film, reinforced with striped/mesh fibres and coated with synthetic rubber or acrylic pressure sensitive adhesive on one or both sides. It is characterised by high Tensile Strength, good abrasion resistance, no residual adhesive removal and good flexibility.

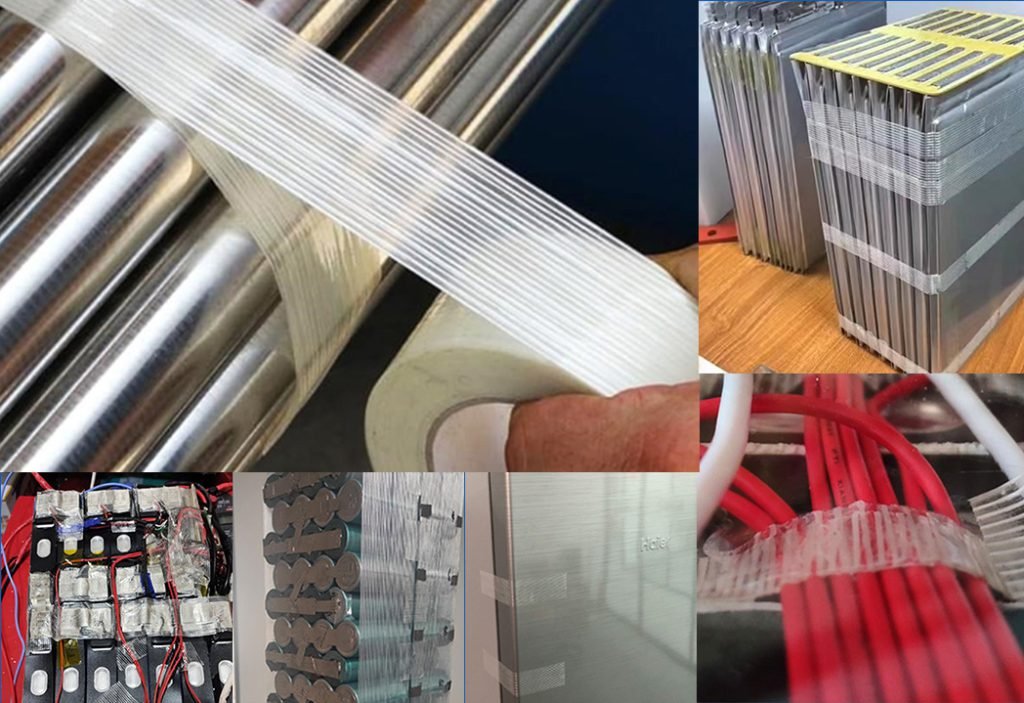

1. New energy industry, lithium battery packaging fixing and assembly strapping.

2. Conventional applications, encapsulating cargo boxes, heavy duty carton sealing and moving heavy goods encapsulation and fixing.

3. Metal industry, coil sealing and steel strapping.

4. Product Code toys, Product Code parts attachment and toy structure fixing and connection.

5. Home appliance industry, large electrical appliances fixed packaging, electrical wiring fixing and temporary fixing of electrical moving parts.

| Property | ||||||||

| Product Code Technical Parameters |

P1201 | P1201W | P1212 | P1214 | P1216 | P1218 | P1239 | P1208 |

| Appearance | Plain | Cross-weaved | Plain | Plain | Plain | Plain | Plain | Cross-Weaved |

| Total Thickness[mm] | 0.14 | 0.13 | 0.114 | 0.137 | 0.155 | 0.173 | 0.16 | 0.3 |

| Backing | PET+Glass Fiber | PP+Glass Fiber | PET+Glass Fiber | |||||

| Adhesive | Hot Melt | Hot Melt | Rubber | Rubber | Rubber | Rubber | Acrylic | Hot Melt |

| 180°Peel Strength[N/inch] | 18 | 18 | 12.7 | 14 | 12.7 | 10.7 | 16 | 22 |

| Tensile Strength[N/inch] | 450 | 550 | 635 | 965 | 762 | 1346 | 950 | 300 |

| Elongation At Break[%] | 3 | 4 | 4 | 4 | 4.5 | 4.5 | 3 | 5 |

| Retentivity[hour] | ≥48 | ≥48 | ≥48 | ≥48 | ≥48 | ≥48 | ≥48 | ≥48 |

| Long-Term Temperature Resistance[℃] | 60 | 60 | 80 | 80 | 80 | 80 | 100 | 80 |

| Short-Term Temperature Resistance[℃] | 80 | 80 | 100 | 100 | 100 | 100 | 120 | 100 |

filament tape is a powerful multi-purpose material. It is mainly made of polypropylene, polyethylene, etc. as the main raw materials, added with a variety of functional additives, and processed through mixing, calendering and other processes. It has good tensile strength, aging resistance, adhesion and long-lasting stickiness.

There are two conventional types, one is striped filament tape, and the other is grid filament tape.

1.Excellent stickiness and fixing ability: The glue of filament tape has strong stickiness, can firmly bond various materials, is not easy to fall off, and effectively fixes and protects the adhered items.

2.Good wear resistance and stretchability: The fiber material of the filament tape has excellent wear resistance and stretchability, which means that it can maintain stable performance during long-term use, is not easy to wear, and at the same time can be used during use. Withstand a certain amount of tension.

3.Good high temperature resistance and water resistance: The glue of the filament tape can maintain its performance in high temperature and humid environments, which allows it to play a good fixing and protective role under various environmental conditions.

Application areas

1.Electronic and electrical fields: filament tape is used for encapsulation, fixation and protection of electronic and electrical components, and can also be used for insulation protection of printed circuit boards, etc.

2.Transportation field: filament tape ensures that packages are securely fastened to trucks or ships, preventing damage due to shock or collision.

3.Construction and Home Life: filament tape is used to strengthen walls or floors, refinish furniture or other items.

4.Logo and decoration: filament tape is used to mark different types of items or as decoration in handicraft making and home decoration.

Size:

Length: The length of filament tape usually varies from a few centimeters to several meters to suit the needs of different occasions. For example, short tapes can be used for small areas of repair and fixing, while long tapes are suitable for encapsulation and bundling of large areas.

Width: In terms of width, filament tapes also come in a variety of options. Common widths include 10mm, 20mm, 30mm, etc., but wider or narrower tapes can also be customized according to special needs. Narrower tapes are suitable for detail work and precise fixing, while wider tapes are suitable for applications requiring a larger bonding area.

Thickness: The thickness of filament tape is also an important factor affecting its performance and use. Common thickness specifications include 0.1mm, 0.15mm, 0.2mm, etc. Thinner tapes are more flexible and easier to use, while thicker tapes are more adhesive and durable.

Specification data