A complete catalog of organic silicone materials for new energy

Yousan Technology will introduce organic silicone products in the field of new energy. Our silicone rubber products include organic silicone foamed sheets, organic silicone solid sheets, and derivatives of organic silicone. Specifically categorized as foamed silicone rubber, silicone sheets, soundproof silicone sheets, thermal conductive pads, ceramicized silicone rubber, and various other products. We provide innovation and research and development of electronic-grade organic silicone products, offering comprehensive solutions for organic silicone products to assist you in selecting suitable organic silicone materials. These products can be used in various fields such as electronics and electrical appliances, solar photovoltaics, new energy packs, rail transportation, and manufacturing.

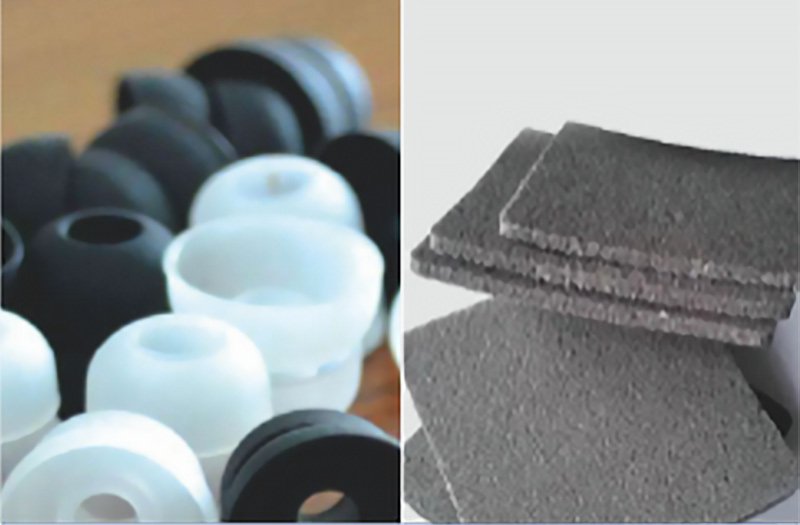

1. Foamed silicone foam

Foamed silicone foam is a foam material formed by the foaming of polysiloxane, retaining the excellent characteristics of organosilicone polymers, such as high and low-temperature resistance, UV and ozone resistance, weather resistance, insulation, and environmental protection. It also possesses the characteristics of foam materials such as low density, excellent sound absorption, and seismic resistance. Its excellent compressive deformation resistance, creep resistance, flame retardancy, and mechanical fatigue resistance make it an ideal material for various high-performance sealing, shock absorption, cushioning, sound insulation, protection, insulation, fire prevention, sound absorption, and noise reduction applications.

![]()

Application Areas

Aircrafts/high-speed trains/automobiles/energy storage/telecommunication and electrical cabinets/communication equipment/lighting/smart devices/cables and optical fibers, etc.

Typical applications

High-speed Rail Shock! Absorption Cushioning

Sound Absorption And Noise Reduction

EMI and RF Shielding Gaskets Pack Box Sealing Waterproof Liquid Cold Plate Shock Absorption Outdoor Electrical Gasket Car Insulation Automotive Heat Insulation

Explosion-Proof Valve

Features

1.Excellent resistance to compression deformation and creep properties.

2.Excellent performance under extreme temperatures.

3.Meets the strictest UL flame retardant ratings.

4.Resistant to mechanical fatigue.

5.High oxygen index, low smoke, low toxicity.

6.Resistance to ozone and ultraviolet radiation.

Product parameter table

Model P57200 P57210 P57220 P57240 P57270 P57280 P57540 P57560 P57700 P57900 ROGERS corresponding model BF-2000 BF-1000 HT-870 HT-800 HT-820 HT-840 Density (g/cm³) 0.18±0.04 0.22±0.04 0.26±0.04 0.37±0.04 0.42±0.04 0.5+0.04 0.4±0.1 0.6±0.1 0.7±0.1 0.9±0.1 25% compression set stress(kPa) 10±4 20±10 35±10 75±20 110±20 145±30 110±30 145±30 400±200 500±200 Tensile Strength(MPa) ≥0.1 ≥0.15 ≥0.2 ≥0.3 ≥0.4 ≥0.5 ≥0.3 ≥0.5 ≥0.6 ≥0.8 Elongation At break ≥70 ≥70 ≥80 ≥80 ≥85 ≥90 ≥40 ≥40 ≥40 ≥40 Compression Set(%) ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 Water Absorption(%) ≤10.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 ≤5.0 Dielectric strength(kV/mm) ≥2.0 ≥2.0 ≥2.2 ≥2.5 ≥3.5 ≥4.0 ≥3.0 ≥4.0 ≥4.0 ≥4.0 Volume Resistivity (Q·cm)

≥1.0*10¹⁴ Thermal Conductivity W/(m·K)

0.05 0.06 0.07 0.08 0.09 0.1 – – – – Product thickness 0.8, 1.6, 2.4, 3.2, 4.8, 6.4, 9.5, 12.7mm

2. Silicone sheet

The P6900 series silicone sheets are prepared from addition-type silicone rubber catalyzed by platinum. They not only possess high mechanical strength and excellent flame retardancy but also are odorless, halogen-free, and environmentally friendly. This material exhibits outstanding aging resistance and physical stability at high temperatures, capable of long-term operation within the range of -55°C to 200°C with minimal residual compression deformation. Additionally, it demonstrates excellent electrical insulation properties and can be widely used in industries such as aviation, cables, electronics, electrical appliances, chemical engineering, instrumentation, automotive, construction, food processing, and medical devices. Typically provided in sheet form, it can be coated on one or both sides with PET film, with a high level of adhesion between the PET film and silicone .

![]()

Main features

1.Excellent flame retardancy and fire resistance.

2.Outstanding resistance to compression deformation and creep.

3.Remarkable heat resistance and cold resistance, capable of sustained operation from -55°C to 200°C.

4.Good insulation properties, environmentally friendly.

Product parameter table

Test items unit Testing standards P6900-30 P6900-40 P6900-50 P6900-60 density g·cm-3 GB/T 533-2008 1.40±0.1 1.40±0.1 1.40±0.1 1.40±0.1 hardness Shore A GB/T 531.1-2008 30 ±10 40 ±10 50 ±10 60 ±10 Tensile Strength MPa GB/T 528-2009 ≥ 0.8 ≥ 1.0 ≥ 1.5 ≥ 1.5 Elongation at break % GB/T 528-2009 ≥ 200 ≥ 100 ≥ 100 ≥ 100 Pressure resistance mA 2700V DC 60s ≤ 1 ≤ 1 ≤ 1 ≤ 1 Insulation resistance MΩ 1000V DC 60s ≥ 500 ≥ 500 ≥ 500 ≥ 500 Environmental testing / RoHS , Reach , ELV qualified qualified qualified qualified Flame retardancy / UL94-2013 V-0 V-0 V-0 V-0 Thermal conductivity W/(m·K) GB/T 10295-2008 ≤ 0.5 ≤ 0.5 ≤ 0.5 ≤ 0.5 Dielectric strength kV/mm ASTM D149-09 ≥ 18 ≥ 18 ≥ 18 ≥ 18 Volume resistivity Ω·cm ASTM D257-14 ≥ 1.0*1014 ≥ 1.0*1014 ≥ 1.0*1014 ≥ 1.0*1014 thickness 0.4-5mm

3. Soundproof silicone sheets

P6900-B Soundproof Silicone Sheet is specifically designed to reduce the propagation of sound within internal spaces. It boasts excellent flame retardancy, and while providing soundproofing, it can also suppress the spread of flames and smoke. This material is typically supplied in rolls and can come with PET protective film on one side.

![]()

Main features

1.High flame retardant standard: Flame retardant performance meets international public transportation and aerospace safety standards.

2.High safety: Effectively suppresses flame and smoke spread indices.

3.Excellent soundproofing effect: Soundproofing effect can be achieved by adjusting the material’s surface density.

4.Exceptional aging resistance: Silicone material exhibits good resistance to permanent compression deformation, UV, and other factors.

5.Can operate long-term in temperatures ranging from -40°C to 100°C.

Main Applications

1.Used for soundproofing and noise reduction on train floors, tops, and side walls of high-speed trains, urban railcars, etc.

2.Used for noise reduction in automotive engine compartments, ship engine rooms, and cabins.

3.Wrapped around industrial and civil pipelines prone to noise generation.

4.Used around compressors, ventilation systems, and other equipment to prevent noise propagation.

5.Used on the surface or internal structure of lightweight walls, ceilings, and floors.

Product parameter table

Test items unit Testing standards Technical indicators density g·cm -3 GB/T 533-2008 1.95 ±0.5 hardness Shore A GB/T 531.1-2008 60 ±5 Tensile Strength MPa GB/T 528-2009 ≥ 2.5 Elongation at break % GB/T 528-2009 ≥ 300 Tear Strength N/ mm GB/T 529-2008 ≥ 6 Oxygen Index % GB/T2406- 1993 32~36 Flame retardant / UL94-2013 V-0 Dielectric strength kV/mm ASTM D149-09 ≥ 18 Volume resistivity Ω·cm ASTM D257- 14 ≥ 1.0*10 14

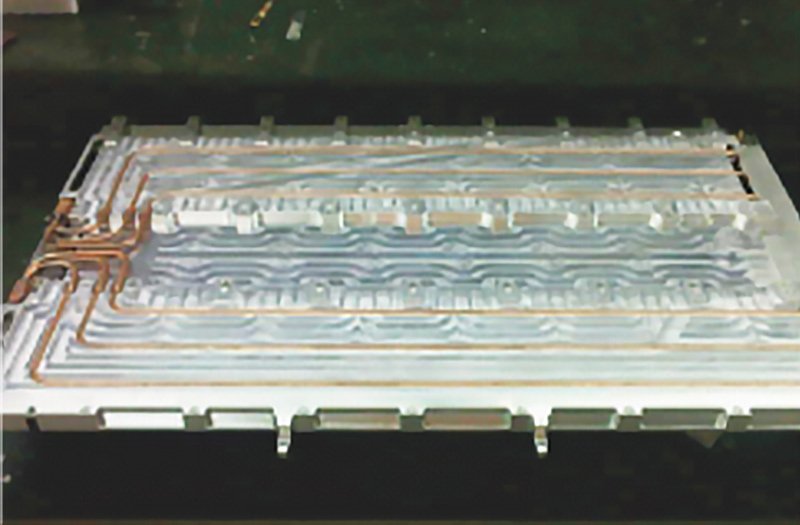

4. Thermal pad

P82200 Thermal Pad

P82200 Thermal Conductive Pad is a cost-effective, flame-retardant, insulating, and thermally conductive soft gel pad. It features damping function and moderate stickiness, making it easy to use. It is particularly useful for filling gaps between low-energy-consumption heat dissipation components and heat sinks, circuit boards, or chassis that require complex die-cut shapes.

Main features

1.Good thermal performance with low interfacial thermal resistance.

2.Compressible on both sides, no internal electromagnetic interference.

3.Easy to use.

Main Applications

1.Computer storage chips.

2.Display driver ICs.

3.CD-ROM/DVD drives.

4.LCD TV backlight units.

5.Between CPUs and heat sinks.

6.Communication equipment.

Product parameter table

Serial number Test items unit Testing standards Technical indicators 1 density g.cm -3 GB/T 6343-2009 2.35±0.1 2 Flame retardant / UL94-2013 V-0 3 Dielectric strength kV/mm ASTM D149-09 ≥ 18 4 Volume resistivity Ω·cm ASTM D257- 14 ≥ 1.0*10 14 5 Thermal conductivity W/(m·K) ASTM D5470- 12 ≥ 2.0 6 Environmental friendly / RoHS qualified

P82300 thermal pad

P82300 Thermal Conductive Pad possesses a certain level of flexibility, excellent insulation, compressibility, and naturally sticky surface. It facilitates heat transfer between heating and cooling components, while also providing damping, insulation, and sealing effects. It meets the design requirements for miniaturization and ultra-thinness of devices, making it an extremely versatile and user-friendly new material widely used in electronic and electrical products.

Main features

1.Excellent thermal conductivity performance.

2.Good insulation performance.

3.Extremely low interfacial thermal resistance.

4.Moderate damping and buffering performance.

5.Self-adhesive for convenient use.

Main Applications

1.RDRAM memory modules.

2.Miniature heat pipe heat sinks.

3.Automotive engine control units.

4.Communication hardware, portable electronic devices.

5.Semiconductor automatic test equipment.

Product parameter table

serial number Test items unit Testing standards Technical indicators 1 density g.cm -3 GB/T 6343-2009 3.0±0.1 2 Flame retardant / UL94-2013 V-0 3 Dielectric strength kV/mm ASTM D149-09 ≥ 16 4 Volume resistivity Ω·cm ASTM D257- 14 ≥ 1.0*10 14 5 Thermal conductivity W/(m·K) ASTM D5470- 12 ≥ 3.0 6 Environmental friendly / RoHS qualified

5. Ceramic Silicone Rubber

P69000C Ceramicized Silicone Rubber possesses excellent electrical insulation, flame retardancy, resistance to high and low temperatures, and aging resistance. The product is halogen-free, non-toxic, and odorless. After combustion, the smoke emission is minimal, leaving behind a ceramic-like hard shell residue. It exhibits good insulation and withstands voltage performance, ensuring the uninterrupted flow of electrical and communication lines during a fire, thereby acting as a barrier to flames and providing insulation protection.

![]()

Main features

1.Excellent electrical insulation and aging resistance.

2.Waterproof and good resistance to chemical corrosion.

3.After high-temperature combustion, it can be transformed into a hard ceramic-like material. The longer the combustion time and the higher the temperature, the more apparent the ceramicization.

4.Good thermal insulation, especially after combustion, the internal honeycomb structure enhances its fire resistance and thermal insulation.

5.Low smoke, non-toxic, and excellent flame retardancy, complying with the EU RoHS directive.

Product parameter table

Test items unit Testing standards Technical indicators density g/cm 3 GB/T 533-2008 1.7±0.1 hardness Shore A GB/T531.1-2008 60 ± 10 Tensile Strength MPa GB/T 528-2009 ≥ 1.0 Dielectric strength kV/mm GB/T 1408-2006 ≥20 Withstand voltage (leakage current) mA DC 3000V,60s ≤1 Insulation resistance MΩ DC 1000V,60s ≥500 Environmental testing / RoHS/Reach/ELV qualified Flame retardancy / UL94-2018 V0 Thermal conductivity W/(m·K) GB/T 10294-2008 ≤0.4 Volume resistivity Ω*cm GB/T 1692-2008 ≥1×10 14

6. P69000 CB Ceramic Silicone Rubber Composite Belt

P69000C-B Ceramicized Silicone Rubber Composite Tape features excellent electrical insulation, flame retardancy, resistance to high and low temperatures, and aging resistance. The product is halogen-free, non-toxic, and odorless. After combustion, it emits minimal smoke and leaves behind a ceramic-like hard shell residue. It exhibits good insulation and withstands voltage performance, ensuring the uninterrupted flow of electrical and communication lines during a fire, thereby acting as a barrier to flames and providing insulation protection.

Main Features

1.Excellent electrical insulation and aging resistance.

2.Good waterproofing and resistance to chemical corrosion.

3.After high-temperature combustion, it can be transformed into a hard ceramic-like material. The longer the combustion time and the higher the temperature, the more apparent the ceramicization.

4.Good thermal insulation, especially after combustion, the internal honeycomb structure enhances its fire resistance and thermal insulation.

5.Low smoke, non-toxic, and excellent flame retardancy, compliant with the EU RoHS directive.

Product parameter table

Test items unit Testing standards Technical indicators Testing standards Technical indicators density g/cm3 GB/T 533-2008 1.7 ±0.1 GB/T 533-2008 1.7 ±0.1 thickness mm / 0.2≤T≤0.8 / 0.8<T≤2.5 Tensile Strength MPa GB/T 528-2009 Silicone Rubber GB/T 528-2009 GB/T 528-2009 Silicone Rubber ≥ 1.0 Composite belt ≥15.0 Composite belt ≥ 15.0 Breakdown strength kV/mm GB/T 1408-2006 ≥20 GB/T 1408-2006 ≥ 20 Withstand voltage (leakage current) mA DC 3000V, 60s ≤1 DC 3000V, 60s ≤ 1 Insulation resistance MΩ DC 1000V, 60s ≥500 DC 1000V,60s ≥ 500 Environmental testing / RoHS/Reach/ELV qualified RoHS/Reach/ELV qualified Flame retardancy / UL94-2018 V0 UL94-2018 V-0 Insulation resistance at high temperatures MΩ 800℃, 5min >0.3 1000 ℃ flame impact for 30min Not burned through Thermal conductivity W/(m·K) GB/T 10294-2008 ≤0.4 GB/T 10294-2008 ≤ 0.4 Volume resistivity Ω*cm GB/T 1692-2008 ≥1×1014 GB/T 1692-2008 ≥1 ×1014